Stonics Built World

Crafting Excellence in Granite Processing

Welcome to the world-class granite processing facility of Stonics Group, located in the stone-rich region of Rajsamand, Rajasthan, India. Here, we transform raw granite blocks—sourced from trusted quarries across India—into precision-crafted slabs and tiles that meet the expectations of architects, importers, and developers worldwide.

At Stonics, quality is not just a process; it’s a promise. Our factory is equipped with the latest cutting-edge technology, enabling us to offer bespoke finishes like edge profiling, mirror polishing, calibration, and surface treatments—all aligned with international quality norms.

Every slab that leaves our unit reflects:

- Consistent sizing and pattern matching

- Rigorous quality checks

- Adherence to global standards from extraction to export

With a strong commitment to customer-centric manufacturing, we ensure that every detail—from the cutting and polishing to final packing and loading—is handled with precision, care, and compliance.

Multi Blade Automatic Cutting Machine

Full Automatic Granite Line Polishing Machine

Storage Area

Block Storage Bay

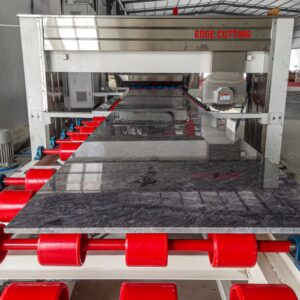

Edge Cutting Machine

Block Dressing Machine

Resin Line

16 Head line Polishing machine

Multi-Cutter Machine

Multi-Cutter Machines

The Granite Multi-Cutter Machine is a highly specialized piece of equipment designed for the stone industry. It is specifically engineered to cut granite blocks into precise slabs or tiles with exceptional efficiency. Built to handle the hardness and density of granite, this machine ensures high performance and durability, making it an indispensable tool for granite processing.

Line polish machine

Line polish machine

A line polishing machine for granite is an advanced, automated solution widely used in the stone industry for polishing granite, marble, and other stone slabs with precision and efficiency.

Key Features:

- Automation Options: Offered in both automatic and fully automatic grades for seamless operation.

- Application: Perfectly engineered for polishing granite, marble, and stone slabs with exceptional results.

- Durable Design: Known for their robust build, these machines require minimal maintenance.

- Head Variants: Available in configurations such as 6-head, 9-head, and 12-head models, delivering superior polishing efficiency.

- Heavy-Duty Build: Depending on the model, the machines can weigh approximately 29 tons.

Bridge cutting machine

Bridge cutting machine

A bridge cutting machine is a specialized tool used to cut and shape granite slabs or blocks with high precision. These machines are vital in the stone processing industry, offering advanced features for efficient and accurate operations.

- Types of Bridge Cutting Machines

CNC Models: 4-axis or 5-axis technology for flexible and intricate cutting.

Automatic Machines: Ideal for high-volume production.

Manual Machines: Suited for custom or smaller projects.

- Applications

Bridge cutting machines are used to create granite slabs, countertops, custom shapes, and sculptures. They can achieve cutting speeds of up to 50 feet per hour, making them efficient for large-scale production.

- Advanced Technology

Equipped with CNC technology, these machines offer unmatched precision and consistency, reducing waste and optimizing efficiency in granite processing

5 Ton Forklift

5 Ton Forklift

The term “5-ton forklift granite” refers to forklifts specifically designed to handle heavy materials such as granite or marble blocks, typically weighing around 5 tons. Specialized forklifts for the granite and marble industries are crucial for efficiently managing these heavy loads.

Granite and marble block forklifts are purpose-built models that cater to the unique needs of these industries.

One such model is the Maximal Compact 5 Ton Diesel Forklift, designed to handle heavy-duty lifting tasks with ease.

Additionally, specialized attachments like the “MS Marble Attachment Forklift” are available, providing tailored solutions for the safe and efficient handling of marble and granite blocks.

- Heavy-duty

- Specialized

- Attachments

Our Workshop Infrastructure